Industrial Humidifier

Printing

Greenhouse

Cleanrooms & Laboratories

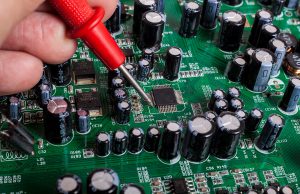

Electronic Manufacturing

Packaging

Hospital & Healthcare

Textiles

Data Centre Humidification & Cooling

Pharmaceuticals

Grocery Stores

Egg Hatchery

Cheese Curing

i) Condair RS - Resistive Steam humidifier

This electric steam humidifier delivers accurate humidity control without the expense of plastic disposable boiling cylinders and simplifies maintenance with its patented scale management system.

Scale that forms on the heating elements breaks off under normal operation and falls into the externally located scale collector tank. Scale removal is a simple process of draining the scale collector tank with the push of a button, allowing the unit to cool then disconnecting the tank and emptying it.

The Condair RS can operate with mains water to provide ±3%RH control or on reverse osmosis (RO) water to offer ±1%RH control. When operating on RO water, scale build-up is virtually eliminated, significantly reducing the unit’s required maintenance.

By locating the water inlet and drain between the twin walls of the outer cylinder wall and an inner cylinder liner, the temperature is kept at a level that inhibits scale formation in this area. This “cold water pool” prevents blockages of the inlet and drain by scale to further enable extended periods between servicing.

An advanced touch screen controller provides intuitive control over operation and very detailed reporting, including downloading performance, fault and service history into Excel for advanced diagnostics. BMS connectivity is standard with BACnet and Modbus protocols.

ii) Condair EL - Electrode boiler steam humidifier

The Condair EL electrode boiler steam humidifier provides reliable steam humidification and is easy to install, use and service. It can be used with steam lances to humidify an air handling unit or duct, or with a fan unit to directly humidify a room.

The steam cylinders of the Condair EL last up to three times longer than similar models due to advanced water quality management. The mineral content of the water is precisely monitored and managed. Water with high mineral content is drained and fresh water added only as required, thus minimising scale build-up and reducing the energy needed to heat fresh water.

When servicing is needed, the Condair EL’s design makes it easy to drain, remove and replace the disposable steam cylinders, keeping downtime to a minimum. Cleanable cylinders are also available.

An advanced touch screen control panel makes operation simple while providing detailed diagnostic reporting. A USB connection allows performance data to be downloaded into Excel and the humidifier’s software to be easily updated.