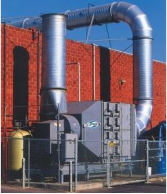

Industrial Air Pollution Control

Plastic Processing

Food Processing

CNC Machining

Laser Cutting

Woodworking

Textiles

Pharmaceuticals

Welding

Industrial Cooking

Chemical

Screw Machining

Paper & Pulp Industry

Infineon Melaka

Kato Manufacturing

B Braun Medical Industries

George Kent

Hai Soon Leong Sdn Bhd

Panasonic Manufacturing

Shorubber

Shin Etsu

Electrostatic Precipitation Technology (ESP) is the key to the superior performance of the Smog Hog. Unlike bag or box filters that remove only the largest particles, Smog Hog electrically charges even microscopic contaminants, and then captures them magnetically in an aluminum collection cell. As a result, this sophisticated electronic solution leaves virtually no grease or hazardous particle untouched, releasing only clean air from the system. UAS’s ESP technology ensures constant airflow, unlike barrier filters that can plug and become ineffective.

Electrostatic Precipitation Technology (ESP) is the key to the superior performance of the Smog Hog. Unlike bag or box filters that remove only the largest particles, Smog Hog electrically charges even microscopic contaminants, and then captures them magnetically in an aluminum collection cell. As a result, this sophisticated electronic solution leaves virtually no grease or hazardous particle untouched, releasing only clean air from the system. UAS’s ESP technology ensures constant airflow, unlike barrier filters that can plug and become ineffective.