Heat Recovery Wheels

A heat exchanger or heat recovery wheel is an energy-saving device that recovers and reutilizes energy lost in ventilation of buildings and factories. As latent heat (humidity) as well as sensible heat (temperature) can be recovered in exchange, it has a high energy-saving effect, and different types of products have been manufactured in various countries. In order to give it a latent heat (humidity) exchanging function, desiccants are used as silica gel, alumina, and synthesized zeolite. However, because these materials absorb odors as well as humidity, they have become the cause of claims against offensive odor generation due to odor transfer. This problems occurs because of preferential adsorption when outdoor air humidity increases supply air cross-contamination.

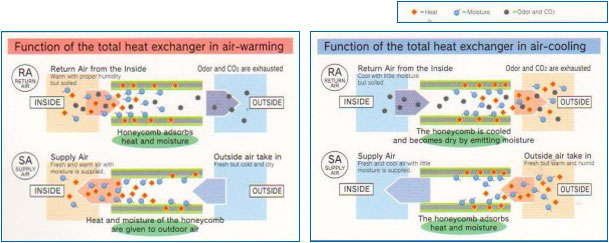

A honeycomb rotor for total heat exchange is rotated between supply and exhaust air zones at the speed of around 16 rpm. When return air from the inside is passed through the rotor, most of the total heat (temperature and humidity) in the exhaust air is kept in the rotor and only the dirty air is exhausted. On the other side of the rotor, outdoor air is taken in through the lower half of the cassette where it passes through the rotor. That outdoor air receves the total heat that the rotor has kept. The incoming air is continuously supplied to the building, pre-cooled and dehumidified in summer and pre-heated and humidified in winter. That is to say, a total heat exchanger is energy –saving device that recycles energy lost in ventilation.

Heat recovery ventilation can be stand-alone devices that operate independently, or they can be built-in, or added to existing HVAC systems. For a small building in which nearly every room has an exterior wall, then the Heat Recovery Ventilation device can be small and provide ventilation for a single room. A larger building would require either many small units, or a large central unit. The only requirements for the building are an air supply, either directly from an exterior wall or ducted to one, and an energy supply for air circulation, such as wind energy or electricity for a fan. When used with ‘central’ HVAC systems, then the system would be of the ‘forced-air’ type.

Office Building

Lecture Halls

Hospitals & Healthcare Centres

Hotels

Vessels

Factories

Laboratories

Schools

Pharmaceutical Manufacturing

Operation Theaters

Casinos

Supermarkets

Parcel F, Putrajaya

Prudential Tower

W Kuala Lumpur Hotel

Hotel Equotorial

ibis STYLES Kota Kinabalu

KPJ Kuching Specialist Hospital, Sarawak

Columbia Asia Hospital Tebrau

Pusat Perubatan Universiti Malaya (PPUM)

IKEA Johor

Hospital Selayang

Mahkota Medical Centre

KPJ Perlis

Institut Jantung Negara

Manipal International University

Jabatan Kimia Terrenganu

Mosti, Penang